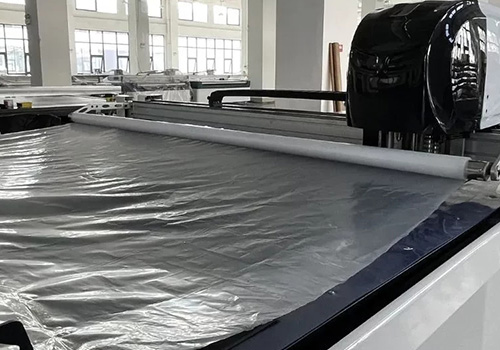

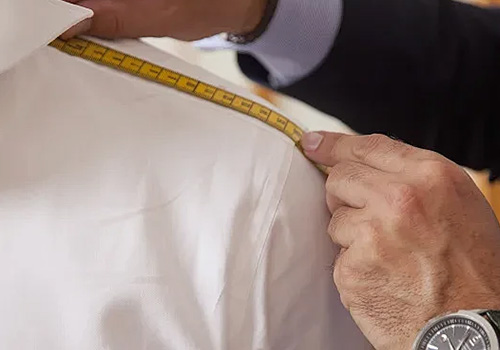

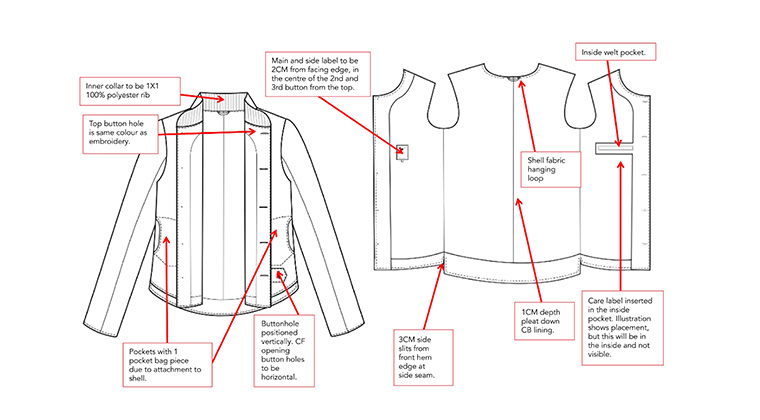

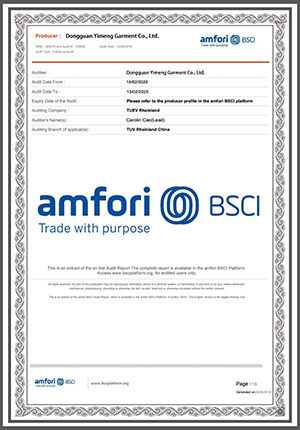

Our pants workflow is described as a clear eight-step process from first brief to shipment. It starts with Inquiry & Brief to clarify product mix, market, target prices and timelines, followed by Fabric/Trim Selection and Tech Pack & Pattern work. We then move into Sample production for fit, print, embroidery or sublimation approvals, and Pre-production Confirmation to lock specs, colours, branding and size curves. Bulk Production covers cutting, sewing, decoration and inline checks, then QC & Packing applies final inspections, folding, bagging and carton packing before Shipping and Replenishment planning.