- MOQ 100+

- Samples 7–10 days

- OEM/ODM

define sport, channels and volumes

choose jersey silhouettes, collars and sleeves

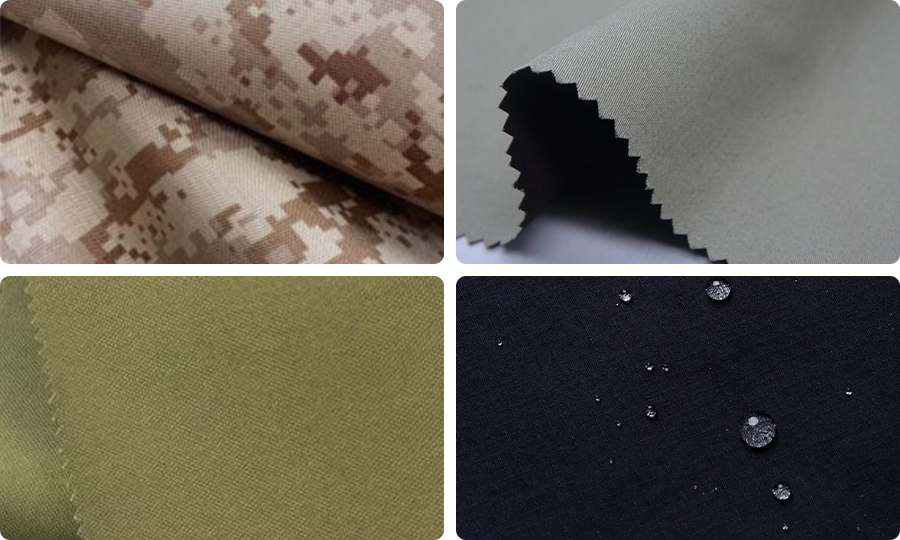

confirm fabrics, meshes, ribs and labels

prepare logos, sponsors, numbers and packaging

build sets, check fit and movement

lock colours, graphics, specs, grading

cut, print, sew and run inline QC

pack by ratio, label cartons and dispatch