- Samples 7–10 days

- Standard MOQ 100 pcs per color/style

- AQL 2.5/4.0

- US/CA/UK/AU/EU

| STEP | Stage | What We Check | Why It Matters |

|---|---|---|---|

| STEP 1 | Fabric inspection | Stains, yarn defects, colour shading | Avoids cutting defective fabric |

| STEP 2 | Wash & shrink tests | Dimensional change, handfeel, colourfastness | Ensures final fit and stability |

| STEP 3 | Print & embroidery QC | Artwork position, clarity, colour, fastness | Protects brand artwork & logos |

| STEP 4 | In-line sewing checks | Seams, construction details | Catches issues before they repeat |

| STEP 5 | End-of-line pre-check | After trimming/ironing | Ensures clean finish by bundle |

| STEP 6 | 100% QC by QC team | Full piece-by-piece check | Aligns to AQL and buyer standards |

| STEP 7 | Pre-packing supervisor audit | Random carton-level audit | Confirms QC consistency |

| STEP 8 | Packing & carton checks | Piece count, size ratio, labels | Prevents carton mix-ups & shortages |

We inspect incoming fabric rolls on inspection machines under proper lighting.

QC checks for:

Stains, oil marks, dirt and dust

Snags, pulled yarns, holes and thick/thin places

Colour shading between rolls and within rolls

Width and weight consistency

Defective sections are marked and recorded so they are not placed into production.

Before bulk cutting we run wash and shrinkage tests on each main fabric.

Typical checks include:

Dimensional change after recommended wash

Handfeel and surface change

Basic colourfastness to washing

Shrinkage data is shared with pattern and marker teams so production patterns are adjusted to keep your final fit on-spec.

All printing, embroidery and appliqué passes a dedicated check point:

Artwork size and placement against tech pack

Colour accuracy versus approved strike-offs

Stitch density and coverage on embroidery

No missing stitches, loose threads, ghosting or cracking

Only approved panels move to sewing.

During sewing, line QC performs in-line inspections by operation:

Seam type and stitch length

SPI and tension balance

Matching of panels, pocket positions and plackets

Correct trims and thread colours

Defective pieces are sent to repair, and recurring issues trigger immediate feedback to line leaders.

After thread-trimming, ironing and basic finishing, we run an end-of-line pre-check by bundle:

Overall appearance and measurements on sample pieces

Zips, snaps and buttons functioning correctly

Clean garments with no stains or marks

Only bundles that pass this gate move to 100% QC.

A dedicated QC group performs 100% piece-by-piece inspection against our checklist and your spec.

They confirm:

Size and measurements within tolerances

Construction and seams without major or critical defects

Branding, labels and hangtags correctly applied

Garments are separated into pass, rework and reject categories, with records kept for every batch.

Before packing, a line or department supervisor runs an additional audit:

Random re-check of QC-passed pieces

Confirmation that corrections have been implemented

Visual review of finishing quality by size and colour

This second layer helps keep QC standards consistent between shifts and styles.

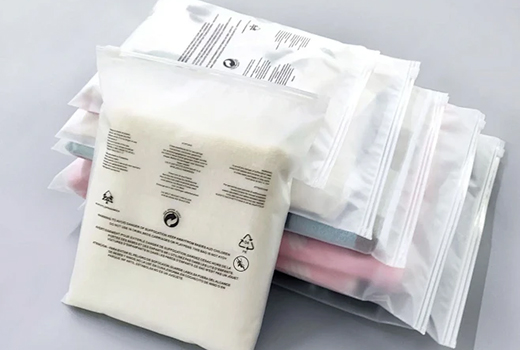

At packing, our team verifies counts and labels so cartons arrive ready for your DC:

Piece count per polybag and per carton

Size ratios and colour breakdown per your packing list

Barcode, size stickers and carton marks

Only after QC signs off on the packing checklist are cartons sealed and moved to the warehouse.