- MOQ 100+

- Samples 7–10 days

- OEM/ODM

Durable twill or canvas trousers for industrial crews and uniform programs with reinforced stress points

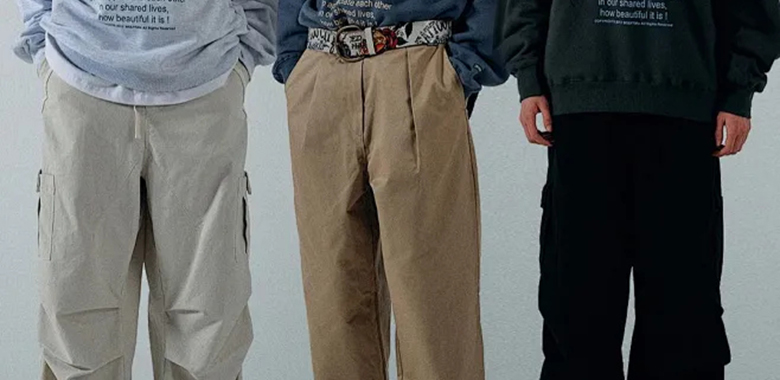

Multi-pocket cargos for streetwear drops or utility-focused lines, available in relaxed or tapered blocks

Fashion-led woven or knit pants with modern fits, panels and trims tuned for capsule collections

Fleece and knit joggers for lifestyle, loungewear and team travel sets with cuffed or open hems

Lightweight tricot or woven track bottoms for training, clubs and fanwear, often paired with matching jackets

Straight, slim or relaxed denim fits with multiple wash levels for core lines and capsules

| Type | Best For | Shell /Lining | Branding | Notes |

|---|---|---|---|---|

| Work Pants | Industrial workwear and uniform contracts | Heavy twill or canvas with reinforcements | Waist patches, thigh logos, woven labels | Focus on durability, abrasion resistance and safety |

| Cargo Pants | Utility lines and streetwear capsules | Mid-weight twill, ripstop or stretch wovens | Pocket embroidery, rubber patches, printed labels | Multiple pocket layouts, tapered or relaxed fits |

| Streetwear Pants | Fashion-led lifestyle collections | Mixed wovens, technical fabrics, panelled builds | Embroidery, side prints, tapes, branded drawcords | Emphasis on silhouette, details and trim stories |

| Joggers & Sweatpants | Loungewear, athleisure and travel sets | Fleece, French terry or heavy jersey | Thigh embroidery, screen prints, jacquard waistbands | Cuffed or open hem, elastic or hybrid waists |

| Tracksuit Pants | Team training, clubwear, fanwear | Tricot, lightweight poly or stretch wovens | Leg logos, stripes, heat transfers, numbers | Often paired with matching tops for full sets |

| Denim Pants & Jeans | Core denim lines and capsules | Various denim weights, rigid or stretch | Back patch, pocket embroidery, printed pocket bags | Wide range of fits, washes and surface effects |

Vanrd sources pants fabrics ranging from cotton twill, canvas and ripstop to stretch wovens, technical shells, fleece, French terry and various denim weights. We match yarn counts, gsm and stretch levels to your durability, comfort and price targets. Trims include zippers, buttons, snaps, drawcords, elasticated waists, belt loops, pocketing fabrics, reinforcement panels and bartacks. Together we balance movement, longevity and visual character for each pants category in your line.

Branding on pants often needs to be both durable and discreet. We support thigh and back-pocket embroidery, small screen prints, reflective or rubber logos, woven badges, jacquard tapes and branded drawcords. Private label details include woven main and size labels, care labels, hangtags, barcoded stickers, branded polybags and printed cartons. Once approved, these branding packages can be reused across seasons, helping multi-style programs stay visually consistent and easy to reorder.

We help independent and established labels build coherent pant ranges alongside tops, aligning silhouettes, fabrics and trims across capsules and core programs while keeping MOQs realistic for growing volumes.

Talk With Our TeamDistributors and Wholesalers: For wholesalers and regional distributors we focus on stable specs, reliable capacity and carton-ready packing so pants programs can be replenished efficiently across multiple markets and channels.

Plan Bulk ProgramsCorporate and Uniform Buyers: Corporate, hospitality and education buyers need easy-care pants with consistent sizing, colours and branding; we support tender-style planning, size curves and documentation for long-running uniform contracts.

Connect With Production TeamPants pricing depends on fabric type and weight, level of reinforcement, pocket and panel complexity, chosen washes or brushing, branding coverage and packaging requirements, plus total volume per colour and style. Minimum order quantities typically start from 100 pcs per colour and style, with full size runs inside that total. This level fairly covers pattern development, sampling and private-label setup, while unit costs generally improve as quantities rise thanks to cutting efficiency, fabric utilisation, trim usage and decoration economics.

Clarify product mix, market, target prices and timelines

Choose base blocks and key variations for pants

Propose suitable fabrics, linings and hardware packages

Produce fit, print, embroidery or sublimation samples for approval

Confirm specs, colours, branding and size curves

Cut, sew, decorate and finish garments with inline checks

Apply final inspections, folding, bagging and carton packing

Arrange shipment, discuss reruns and future volumes