- Samples 7–10 days

- Standard MOQ 100

- AQL 2.5/4.0

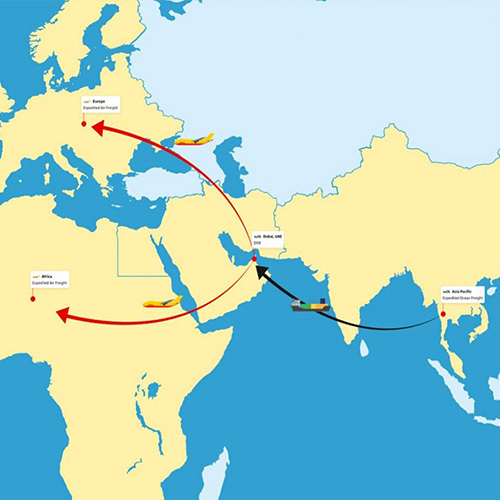

- US/CA/UK/AU

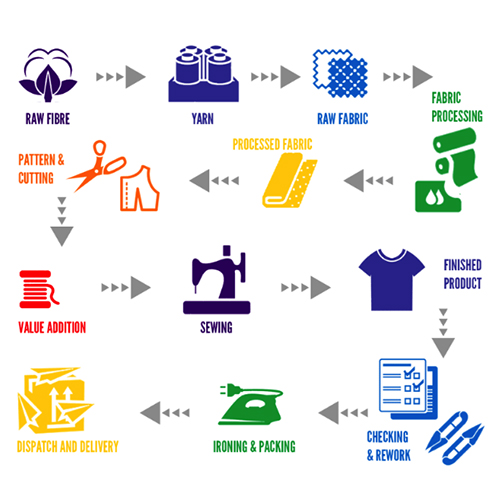

Project kickoff with clear roles, calendar and deliverables.

Market scans and mood boards.

Woven & knit blocks with US/EU grading.

Fabric ladders, colorways & graphics.

Jackets & fleece mockups and quick iterations.

Embroidery/screen/DTF adhesion after wash.

Construction, trims and measurements locked.

Twill, denim, nylon/poly, satin, canvas, jersey/fleece.

Taffeta, tricot, mesh, quilt, down/synthetic.

Zips, snaps, rib knit, elastics, woven/heat labels.

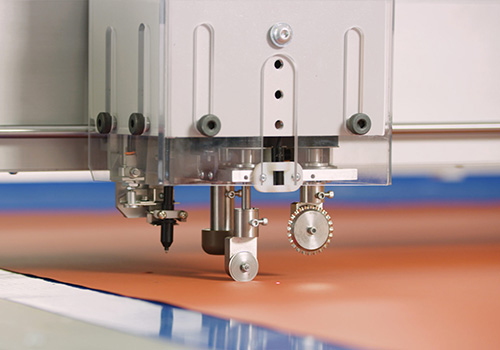

Optimized markers for yield.

Bar‑tack, keyhole, coverstitch.

Inline checks, final AQL 2.5/4.0.

Hangtags, barcodes, cartons.

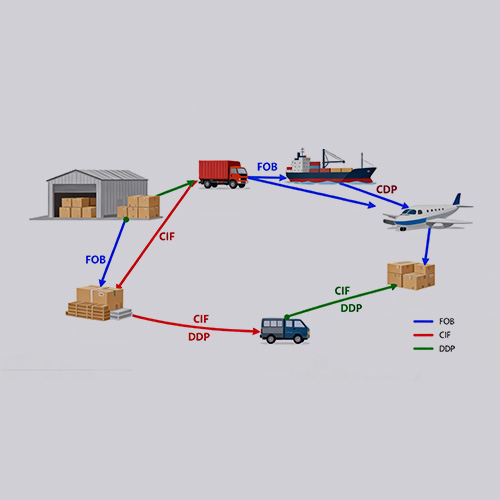

FOB/CIF; DDP on request.

Realistic calendars with risk notes.

Provide your design, spec and size charts. We industrialize patterns, build samples, confirm PP, and deliver bulk that matches your brand standards across woven outerwear and knit fleece/jersey programs.

Graded charts and tolerances.

Woven constructions & knit coverstitch.

GSM, shrinkage & yields.

Tests & AQL notes.

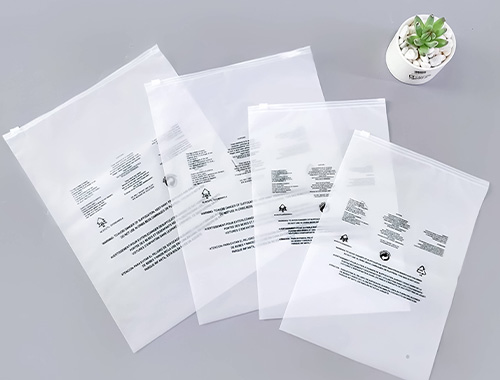

Zips/snaps/labels/hangtags/packaging.

Embroidery/print/appliqué maps.

Outerwear & knit lines with auto‑cutting.

Realistic calendars & global service.

ISO‑referenced QC and AQL inspections.