- MOQ 100+

- Samples 7–10 days

- OEM/ODM

(use case, target retail, margin)

(flight satin vs Taslan vs leather)

(classic/boxy/oversized)

(shade bands if garment dye)

(zipper cycle/snap pull tests)

Our QC process for bomber jackets starts before bulk fabric is even cut. Shell and lining materials are checked for shade, defects and handfeel, and any coated or printed nylon is tested with trial prints to make sure inks or transfers do not crack or peel. During development we issue a PP sample that locks in shell, quilting, trims, branding and measurements. When bulk production begins, our team performs inline inspections focused on critical points such as zipper operation, snap pull strength, rib seams and quilting alignment. We also run sample garments through cycle tests for zippers and basic wash tests to validate performance. Only after final inspection do we pack and ship cartons according to your packing requirements and destination country standards, helping your brand reduce return rates and quality claims.

For bomber and flight jackets, our standard minimum order quantity is 100 pieces per color and per style, making it easier for brands to test new designs without committing to oversized volumes. We normally need around 7–10 days to produce development or pre-production samples once the shell, lining, fit block and branding details are confirmed. Bulk production lead time varies according to fabric booking, whether the jacket is reversible, and the total quantity, but we always provide a clear schedule from sampling to shipment. Pricing is quoted in tiers (for example 100 / 200 / 500 / 1000+ pieces) and reflects shell choice, insulation level, construction complexity and branding method, so you can select the tier that best supports your target retail price and margin.

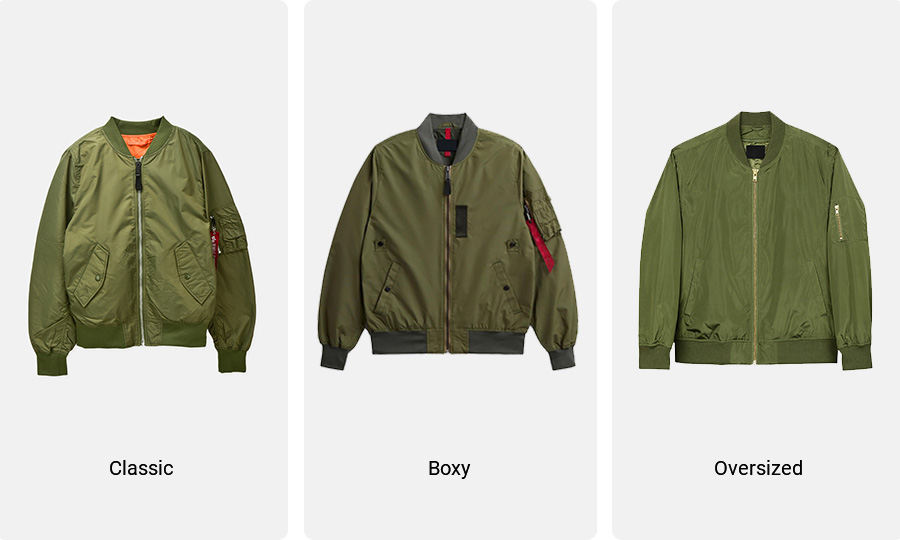

To keep your collections consistent, we maintain three core fit blocks for bomber jackets. The classic block has balanced rib heights and a regular body length; the boxy block is shorter in length with a broader shoulder and fuller sleeve; and the oversized block extends the body and drops the shoulder for a more relaxed, streetwear-oriented silhouette. Standard sizing runs from XS to 3XL, but we can develop custom grading rules based on your existing charts or on reference samples you send us. All blocks are tested for armhole mobility and rib recovery after washing, which is especially important for bomber jackets with heavier insulation or coated shells.

Our bomber jacket programs are built for private label. You can choose from multiple branding techniques including screen printing, DTF and other heat transfers, embroidery, patches and bonded logos. For coated nylon shells we use low-temperature ink systems and always run test panels to check adhesion and cracking before approving bulk. Beyond visible logos, we can develop complete label packs: woven main labels, size tabs, care labels, swing tags and barcodes. Colors can be matched to your shell and rib tones to keep a unified brand look. We respect intellectual property and will only reproduce protected military insignia, squadron patches or registered trademarks when you provide valid authorization.

Reversible bomber and flight jackets are a standard part of our production. We use dual-pull zippers, neat internal seam finishes and carefully placed labels so that each side can function as the “main” outside face. Common colorways include classic sage with orange reverse or more fashion-driven black and neutral combinations.

When planning the graphics, we map out screen prints, embroidery, appliqués and woven badges on both faces of the garment to prevent telegraphing and unwanted impressions. Fabric and insulation choices are also reviewed to avoid excessive bulk, so the jacket keeps a sharp silhouette whether your customer wears side A or side B.

We design the insulation package of each bomber jacket around your climate and retail positioning. For three-season wear we typically use quilted taffeta with fill weights in a practical GSM range, balancing warmth and mobility. For colder markets we can add down-alternative insulation to increase loft and thermal performance without feather leakage, while keeping the bomber profile clean.